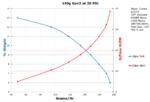

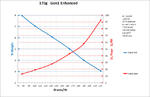

140g @ 10% Wt , 170g @ 5% Wt

PlasmaBlock® Air Cooled

Product Summary

One of the new design Plasma Blocks featuring a one-piece block/heat sink that dissipates heat more efficiently and allows greater ozone generation related to it's overall size. The Gen1 enhanced block generates 170g per hour of 5% Wt. The Gen2 block generates 140g per hour of 10% Wt.

Product Details

- Silent, Rugged, Reliable, Cost-effective

- Fully automatic tuning for constant ozone output and installation simplicity

- Service simplicity due to automatic fault diagnostics

- No exposed high-voltage safety hazards

- Now available with PlasmaVIEW® software (optional).

For additional application information, see the PlasmaBlock® Application Guide Manual.

Design Features

- Wi-Fi and digital communications available as an option.

- Digital communications optional: simple and less expensive.

- Micro Processor based, installation simplicity and automatic tuning for constant ozone output.

- Automatic bus voltage compensation stabilizes output as power line conditions change.

- Pulse Density Modulation (PDM), linear power (ozone) output even at high turn-down.

- Service simplicity due to automatic fault diagnostics.

- Easy interface to PLC or computer.

- Efficient, compact, silent (25khz), safe, rugged, reliable, advanced – all the normal traits of a PTI product. Same precise linear control, with turn down to 1%, as with all Plasma Block® products.

- Maximum up-time , durable, commercial / industrial solution the ozone industry requires.

- Possible cell flooding is identified followed by shutdown and enunciation. No damage is caused to electronics, transformer and rarely the cell. Cell flushing and drying in the field is usually sufficient to restore full service.

- Control connections of the essential I/O functions are the same as all other Plasma Block® products.

- Line voltage 240v and 120v, UL approval pending.

- Military grade conformal coating eliminates problems associated with condensation and mold, and greatly retards damage caused by accidental ozone exposure.

- There is an inherent pressure drop associated with each Plasma Block. This can vary depending on the desired flow. Verification of the outlet pressure, at the desired flow, of the Plasma Block is crucial in order to prevent a negative pressure drop in the Plasma Block. This will damage the Plasma Block internals and is not a warrantied repair.

Configuration options

PTI will set up and tune units to the customers desired specifications.

Oxygen pressure - (10 - 100 psi) (UL 5x rated)

Oxygen flow liters/minute - 5 - 60 slpm

Heat load btu/hr = 4400 btu

Chassis (stand alone)

Inlet fittings (none, 3/8", other)

Outlet fittings (none, 3/8", other)

Weight Lbs (Kg) :

complete package - 37.7 lbs (17.34 Kg)

modular - 32.9 lbs (15.1 Kg)

Related Manuals

(pdf format, view or download)

Installation Operation

Dimension Drawing

How to read the performance graphs

PlasmaBlock Performance Specs (heat dissipation, current, ozone output)

Spec Sheet

DAT210 is the standard control circuit board for this unit.

DAT210 Quick Start Manual

DAT210 Installation and Operation Manual

Product Photos

Output Performance Charts

Training and Instructional Videos

DAT210 Set Power Point

DAT210 Start Button Sweep

DAT210 New Profile Procedure

DAT210 Normal Running

DAT210 LED Fault Indicators

DAT210 Connection Safety Considerations

DAT210 On Delay Timer

Fuse and Power Supply Testing

IGBT and Diode Bridge Testing

16 Pin Kit Testing

DAT210 Firmware 3 1

SSD110 tuning

Installation Drawings