Component Products Overview

Product Summary

Component parts enabling companies to build their own or replace parts of their existing ozone generating equipment as needed. These component parts are the same ones used in existing PTI products. PDM, Voltage and Frequency potentiometers have their own jumper selection for onboard control if desired.

Product Details

PTI now offers Plasma Block component parts enabling companies to build their own or replace parts of their existing ozone

generating equipment as needed.

Prior to this, all PTI ozone generating products included a complete package consisting of an Inverter, Transformer, Ozone

cell and cooling (water and/or air). Now companies can build their own or replace parts as needed.

These component parts are the same ones used in existing PTI products.

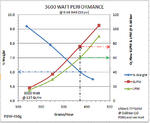

The performance charts below represent performance using 3 ozone cells (the standard PTI 450g unit). A 2 cell installation

will deliver 60% of that output, a 1 cell installation will deliver 30% of that output.

Design Features

- Directly installable by UL 508a panel house.

- Full-Auto and Semi-Auto modes hold constant power over the entire pressure range of 5 - 100psi. From package to process, no setup or adjustments are required. Continuously tracks and automatically optimizes performance for changes in pressure, flow and line voltage.

- Universal, world class product. Constant ozone output and cooling: 100-240vac, 50/60hz, power factor .94 -.99 across the entire working voltage and ower range. Power supply is UL /CSA / CE approved. NO line voltage configuration jumpers, any voltage, any frequency: same unit.

- Efficient, compact, silent (25khz), safe, rugged, reliable, advanced – all the normal traits of a PTI product. Same precise linear control, with turn down to 1%, as with all Plasma Block® products.

- Maximum up-time , durable, commercial / industrial solution the ozone industry requires.

- Possible cell flooding is identified followed by shutdown and enunciation. No damage is caused to electronics, transformer and rarely the cell. Cell flushing and drying in the field is usually sufficient to restore full service.

- Extensive two tier fault enunciation maximizes up-time and simplifies service diagnostics. Latched fault indicators retain fault status until serviced.

- The control electronics is accomplished via Plasma Technics® new DAT300 or 310 microcontroller based inverter board. This state of the art controller yields a simpler user interface and many new features intended to further increase up-time and simplify installation and troubleshooting.

- PDM, Voltage and Frequency potentiometers have their own jumper selection for onboard control if desired.

- Complex and thorough onboard electronic short circuit protection prevent nuisance circuit board failure due to accidental field wiring errors.

- Power and control connections are located at the rear of the product to enable integrators to construct ‘plug & play’ mounting.

- Water connections 3/8" OD.

- Like all other Plasma Block® products, the feed gas supply must be either PSA concentrator or bottle feed of at least

-60°F dew point, filtered, positive-pressure oxygen.

Product Photos

Output Performance Charts

Installation Drawings